The Dielectric Dissipation Factor (Tan Delta) test is a critical method for diagnosing the condition of transformer insulation. It can precisely identify hidden risks such as moisture, aging, and impurities in the insulating oil or solid insulation materials, providing a reliable basis for predictive maintenance.

This article breaks down the core knowledge of Tan Delta testing—from basic definitions, testing necessity, and operation modes to step-by-step procedures and result interpretation—to help electrical engineers and maintenance technicians work more efficiently.

What is Tan Delta (Dissipation Factor)?

Basic Principle (Loss Angle Theory)

Tan Delta (Dielectric Dissipation Factor) is essentially the tangent of the loss angle δ of an insulating material under AC voltage. It reflects the degree to which insulating materials convert electrical energy into heat loss.

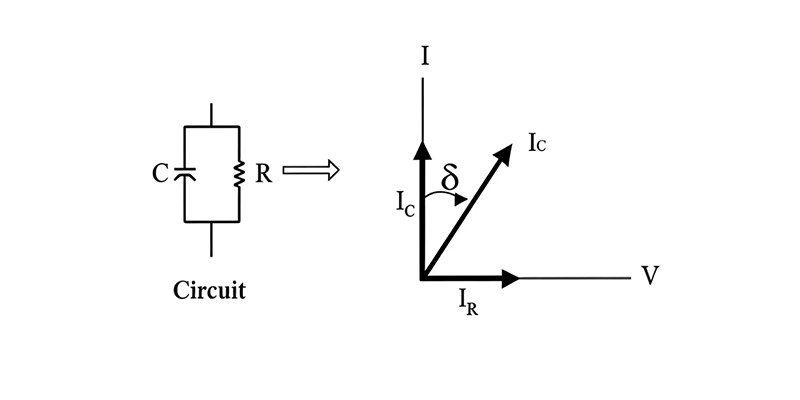

From a circuit perspective, transformer insulation can be modeled as a “Capacitor + Resistor” in parallel:

Capacitive Current (IC): The reactive current of ideal insulation, which produces no energy loss.

Resistive Current (IR): The active current of actual insulation, which generates energy loss due to insulation defects (e.g., dampness, aging).

Loss Angle δ: The phase difference between the total current and the capacitive current. Tan Delta = IR/IC. A larger value indicates more severe insulation loss.

Why Perform Dielectric Loss Testing on Transformers?

The core value of Tan Delta testing lies in identifying potential hazards in the power system early to avoid sudden failures. Its specific functions include:

Detecting Moisture: Precisely detects trace amounts of water in oil and paper insulation, effectively capturing moisture content even below 1%.

Identifying Aging: Insulating materials oxidize and crack after long-term operation, leading to increased loss. Testing provides real-time monitoring of the aging degree.

Locating Impurities: Detects contaminants such as sludge, conductive particles, and carbonization products in the insulating oil.

Predicting Lifespan: Through trend analysis, it evaluates the remaining useful life of the transformer insulation to inform maintenance decisions.

Tan Delta Test Modes: UST, GST, and GSTg

Depending on the grounding status of the test object and shielding requirements, Tan Delta testing is divided into three core modes to adapt to different scenarios:

UST – Ungrounded Specimen Test

Applicable Scenario: Testing insulation between two specific windings (e.g., High Voltage side to Low Voltage side) where isolation from ground interference is needed.

Core Feature: Only measures the current flowing between specified leads to the instrument, ignoring leakage current to ground. The test is highly targeted.

GST – Grounded Specimen Test

Applicable Scenario: assessing the overall insulation status of the transformer with respect to the ground. This is the most commonly used basic test mode.

Core Feature: Measures all leakage current flowing to the earth, reflecting the general working level of the insulation system.

GSTg – Grounded Specimen Test with Guard

Applicable Scenario: Precision testing in areas with severe electromagnetic interference (e.g., near high-voltage equipment or complex wiring environments).

Core Feature: Uses a shielding layer (Guard) to exclude external interference currents, ensuring the measurement results are not affected by the external electromagnetic environment.

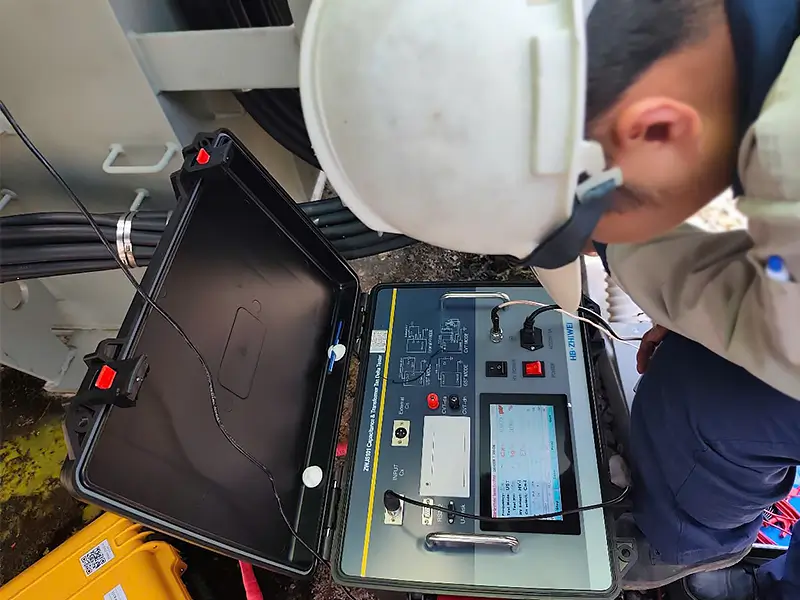

How to Execute Transformer Dielectric Loss Testing (Step-by-Step Guide)

1. Safety Precautions

Disconnect all connections between the transformer and the grid before testing, ensuring complete power outage and grounding discharge.

Clear the test area, keep away from flammable and explosive items, and wear PPE such as insulating gloves and boots.

Check the status of the test instrument, confirm it complies with international standards like IEC 60247, and ensure the calibration is valid.

2. Connection Setup

Connect instrument leads according to the test mode (UST/GST/GSTg): For GST mode, ground the test object securely; for UST mode, ensure the test object is isolated from the ground; for GSTg mode, correctly connect the shielding layer.

Confirm leads are securely connected to avoid measurement errors caused by poor contact. Use shielded cables if necessary to reduce interference.

3. Apply Voltage and Record Readings

Apply AC voltage according to standard requirements (usually 1kV, 2.5kV, or a portion of the rated voltage).

Once the voltage stabilizes, record the Tan Delta value, capacitance, and test temperature. It is recommended to repeat tests at multiple voltage points to verify accuracy.

4. Temperature Correction Factor – A Critical Point

Temperature has a significant impact on results: For every 10°C rise in temperature, the Tan Delta value roughly doubles.

All test results must be corrected to a standard temperature of 20°C (refer to IEC 60247 formulas) to perform valid horizontal or vertical comparisons.

Interpreting Tan Delta Test Results

1. Acceptable Limit Standards

New Transformers (20°C): Tan Delta value < 0.5% (per IEC 60076-10).

In-Service Transformers: Adjusted based on voltage level; 110kV and below < 1.0%, 220kV and above < 0.8% (refer to IEEE C57.12.90).

Core Principle: The trend of change is more important than the absolute value. If the value increases by more than 30% compared to factory or historical data, immediate investigation is required.

2. Analysis Dimensions

Horizontal Comparison: Compare results with transformers of the same model and voltage level to rule out individual differences.

Vertical Comparison: Compare with the unit’s own historical data (corrected to the same temperature) to track trends.

Temperature Consistency: Corrected data should be within a reasonable fluctuation range. If corrected values differ significantly at different temperatures, local insulation defects may exist.

3. Common Anomaly Patterns and Suggestions

High value increasing with voltage: High probability of insulation dampness or oil deterioration. Dielectric breakdown voltage tests for oil are recommended.

Sudden Mutation (increase > 50% vs history): Potential local carbonization, winding deformation, or insulation damage. Combine with Partial Discharge testing for further localization.

Significant difference between windings: Indicates an insulation issue specific to that winding. Check the paper insulation and oil gaps for that specific section.

Tan Delta vs. Insulation Resistance Test

Although both tests act as insulation diagnostics, their core logic and applicable scenarios differ significantly:

| Comparison Dimension | Tan Delta Test | Insulation Resistance Test |

|---|---|---|

| Test Purpose | Assess the overall quality and loss characteristics of the insulation volume. | Find the path of minimal resistance (localized defects) in the insulation. |

| Voltage Level | Low as 1kV up to rated voltage, adaptable to various scenarios. | Usually 500V-10kV, prioritizing high voltage penetration. |

| Sensitivity | Sensitive to trace moisture, aging, and overall deterioration. | Sensitive to obvious breakage, large-area dampness, and conductive paths. |

| Result Interpretation | Requires temperature correction and trend analysis. | Direct resistance reading with clear thresholds (e.g., >1000MΩ). |

| Applicable Scenario | Predictive maintenance, insulation status trend tracking. | Fault troubleshooting, routine insulation compliance checks. |

Summary: The Insulation Resistance Test is like a “detector” that quickly finds obvious “big holes”; the Tan Delta test is like a “full-body scan” that precisely assesses the overall health of the insulation. Using them together covers all insulation diagnostic needs.

FAQ for Dielectric Loss Testing

Q1: Are the acceptable limits for Transformer Tan Delta absolute?

A1: No. Limits must be considered alongside voltage level, insulation type (oil-filled/dry-type), operating years, and specific standards. The core basis for judgment is the trend change—a sudden spike is more dangerous than an absolute value slightly exceeding the standard.

Q2: How does temperature affect test results?

A2: As temperature rises, insulation resistance drops and IR increases, causing the Tan Delta value to rise. You must record the test temperature and correct it to 20°C; otherwise, valid comparisons with historical data or standards are impossible.

Q3: What is the difference between Power Factor and Tan Delta?

A3: The mathematical definitions differ (Power Factor = IR/Itotal, Tan Delta = IR/IC), but for excellent insulation (where δ is extremely small), the numerical values are nearly identical. Regional habits differ: Europe and Asia commonly use Tan Delta, while North America tends to use Power Factor.

Q4: Can Tan Delta testing directly determine if the problem is with the oil or paper insulation?

A4: Not directly. Transformer insulation is a composite “Oil + Paper” system. You must combine it with specific oil tests (oil dielectric loss, moisture content) and paper insulation aging assessments (degree of polymerization) to accurately locate the source of the fault.

Q5: How to reduce electromagnetic interference during field testing?

A5: Prioritize the GSTg shielded mode; keep test leads away from high-voltage busbars and live equipment; shorten lead length and secure their position to avoid stray capacitance; test at night or when grid load is lower to reduce environmental interference.

Conclusion

To ensure the reliability of test results, one must rely not only on standardized operating procedures but also on precision instruments that comply with international standards. High-quality testing equipment can effectively resist field electromagnetic interference and capture weak signals, providing real data support for insulation diagnosis.

Looking for insulation diagnostic solutions for high-voltage equipment?

Accurately interpreting Tan Delta test results requires professional knowledge and precise instrumentation. ZHIWEI provides advanced dielectric loss testers designed specifically for complex electromagnetic environments. With superior anti-interference capabilities and full compliance with international standards like IEC 60247 and IEEE C57.12.90, we ensure you get precise data on transformer insulation health.

Don’t let insulation aging become a hidden danger in your power system. Contact the ZHIWEI technical team today for a free consultation on testing solutions or a product quote, and upgrade your diagnostic toolkit to safeguard the safe operation of your transformers!