As the dielectric medium and coolant for high-voltage equipment like transformers, instrument transformers, and oil circuit breakers, insulating oil must not only dissipate heat and suppress partial discharges but also maintain its insulating properties without breaking down under a strong electric field.

Dielectric strength (also known as Breakdown Voltage or BDV) is the measure of insulating oil’s ability to resist this electrical breakdown. A higher dielectric strength signifies better insulation performance, more effectively preventing unwanted current leakage or short circuits within high-voltage equipment.

Why Test the Dielectric Strength of Insulating Oil?

Safety and Reliability: A lower BDV increases the likelihood of arcing or flashovers inside the equipment, leading to power outages and, in severe cases, equipment damage and fire hazards.

Early Warning and Maintenance Decisions: BDV is highly sensitive to moisture, particles, and fiber contamination, making it a “rapid diagnostic indicator” for detecting issues like aging seals, faulty breathers, or improper maintenance.

Compliance and Acceptance: For new oil deliveries, equipment commissioning, and routine annual or quarterly inspections, BDV is a mandatory test item specified by international standards and OEMs.

Cost and Lifespan: Good dielectric strength translates to lower partial discharge and thermal losses, extending the life of paper insulation and the equipment as a whole, thereby reducing the Total Cost of Ownership (TCO).

In short, BDV is the bottom line for an insulation system. It changes rapidly, is highly indicative, and is one of the most critical parameters to include in routine monitoring.

Factors Affecting Dielectric Strength

A decline in dielectric strength is typically triggered by the following factors (which often interact):

Moisture (Dissolved and Free Water): Polar water molecules reduce the oil’s dielectric strength and increase its dielectric loss factor. Moisture can ingress from external humidity, seal leaks, failed breathers, or be released from paper insulation.

Particles and Fibers: Metal filings, paper fibers, and dust can create a local “tip effect,” intensifying the local electric field and promoting breakdown.

Dissolved Gases and Microbubbles: Gases lower the local dielectric constant and can form channels for arcing. They are often introduced by improper maintenance or oil filling, or insufficient vacuum treatment.

Oxidation and Aging Byproducts: Acidic compounds and sludge alter the oil’s electrical and rheological properties, indirectly reducing its BDV.

Temperature and Humidity: Ambient and operational temperature and humidity affect the moisture equilibrium between the oil and paper insulation, which in turn influences the BDV.

Note: BDV is a “resultant value.” To find the root cause of a low reading, it must be analyzed in conjunction with other indicators, such as moisture content (ASTM D1533/IEC 60814), acid number (ASTM D974), dielectric dissipation factor/permittivity (IEC 60247/ASTM D924), interfacial tension (ASTM D971), and Dissolved Gas Analysis (DGA) (IEC 60567/ASTM D3612).

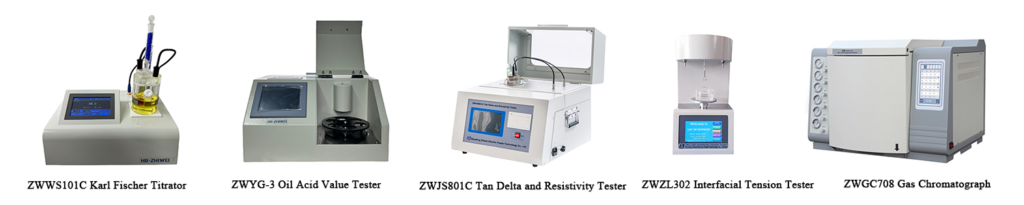

Insulating oil testing equipment

Main BDV Testing Standards and Methods

Different standards specify different electrode shapes, gaps, and stirring methods, meaning their results are not directly interchangeable. The choice of method should align with equipment specifications and prevailing standards in your market.

1. IEC 60156 (Determination of the power frequency electric breakdown voltage)

Scope: Widely used globally for mineral and ester oils.

Features: Uses standard spherical or mushroom-shaped electrodes with a fixed gap. The voltage is increased at a specified rate, and the test is repeated several times to obtain an average.

Advantages: Sensitive to contaminants and effectively reflects the actual condition of in-service oil.

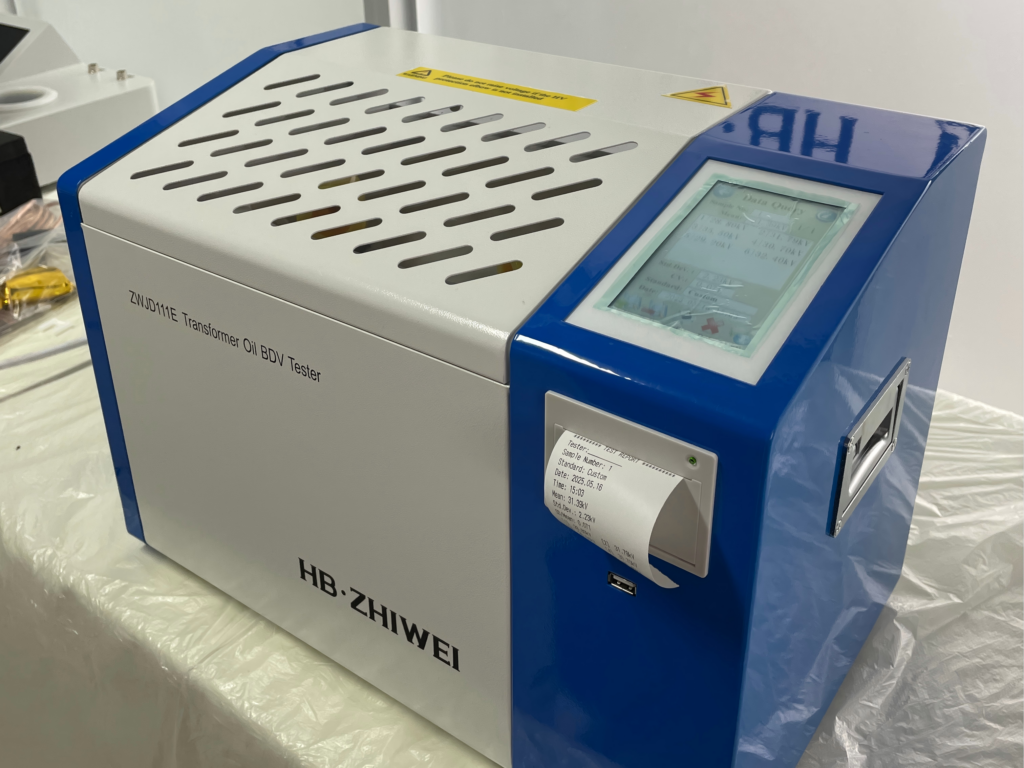

ZWJD111E

2. ASTM D1816 (Using VDE Electrodes)

Features: Employs a smaller gap (e.g., 1 mm or 2 mm) and includes oil circulation/stirring, making it extremely sensitive to trace amounts of moisture and particles.

Application: Used in North America and specific industries for assessing the condition of in-service oil.

3. ASTM D877 (Using Disc Electrodes)

Features: Uses a larger gap and is less sensitive to contamination, often resulting in higher readings.

Application: Commonly used for quick screening of new oil during factory or delivery acceptance; its value for in-service diagnostics is relatively limited.

Caution: BDV values from different methods cannot be directly compared or converted. The selection of a method and interpretation of results must be based on the same standard.

Standardized Sampling and BDV Testing Practices

1. Standardized Sampling (Follow IEC 60475 – Sampling of insulating liquids)

Thoroughly flush the sampling port by draining some oil before collecting the sample.

Use a clean, dry glass bottle with an oil-resistant seal; avoid plastic containers whenever possible.

Prevent air entrapment and exposure to humid environments. Label the sample clearly and send it for testing promptly.

2. Test Preparation

Clean and calibrate the electrodes and their gap (using specified feeler gauges).

Control the rate of voltage rise and stirring parameters according to the standard.

Perform multiple breakdown tests and average the results.

Record the oil temperature and ambient conditions, as the breakdown behavior can vary slightly at different temperatures.

3. Common Sources of Error

Contaminated or burred electrodes; residual moisture/detergent in the sample bottle.

Incomplete removal of air bubbles and micro-particles.

Deviation from the standard procedure or rate of voltage rise.

How to Interpret BDV Test Results (Practical Advice on Thresholds)

New Oil Acceptance: Using IEC 60156 or ASTM D877, the BDV of new oil should be significantly higher than the minimum specified limit. The exact acceptance value depends on the standard, oil grade (e.g., IEC 60296, ASTM D3487 Type I/II), and OEM requirements.

In-Service Oil Monitoring: Focus on trends and relative changes. If the BDV shows a significant drop (e.g., ≥10–15 kV compared to the last measurement or consistently below the facility’s threshold), immediately investigate sources of moisture, particles, and the condition of seals/breathers.

Method Consistency: To perform trend analysis, always use the same standard, electrode gap, and procedure. Do not mix results from different methods.

Correlated Indicators: A low BDV is often accompanied by rising moisture content, increased dielectric loss, and decreased interfacial tension. Combine with DGA to check for abnormal discharge or overheating.

As acceptable limits vary widely based on equipment voltage class, oil type, and regional regulations, it is recommended to consult IEC 60422 (Guide for the maintenance of mineral insulating oils), IEEE Std C57.106 (Guide for Acceptance and Maintenance of Insulating Oil), and the equipment OEM’s manual to establish your own acceptance criteria and action plans.

What to Do When BDV is Low?

1. Rapid Diagnosis

Re-test: Confirm the result and ensure the test method was consistent.

Correlated Tests: Analyze moisture content, dielectric loss, acid number, interfacial tension, and DGA.

2. On-Site Response

Inspect and replace the silica gel in the breather; check for moisture ingress paths and seal integrity.

Perform on-line or off-line vacuum dehydration/degassing and filtration to raise the BDV and lower dielectric loss.

If necessary, schedule an outage for deep drying and oil replacement.

For equipment with high moisture content in its paper insulation, use processes like hot oil circulation or vacuum drying.

3. Root Cause Correction

Improve SOPs for sampling and oil filling procedures.

Increase the frequency of routine moisture and BDV monitoring.

Include oil processing equipment in the regular maintenance and inspection checklist.

Frequently Asked Questions (FAQ)

1. Can results from IEC 60156, ASTM D1816, and D877 be compared?

No. The electrodes and gaps are different, leading to different sensitivity levels and numerical values. Trend analysis must be performed using the same method consistently.

2. The BDV of new oil is high but drops after the equipment is commissioned. Is this normal?

A slight decrease is common, but a significant drop suggests the ingress of moisture or contamination. This requires re-testing and investigation of correlated indicators.

3. Can BDV directly reflect the condition of paper insulation?

BDV primarily reflects the electrical cleanliness of the oil phase. The aging of paper insulation is better assessed through a comprehensive evaluation of DGA, furfural (2-FAL) content, and moisture status.

4. Can BDV be monitored online?

BDV is a destructive test, so direct online measurement is uncommon. Online moisture sensors and dielectric loss monitors can be used to indirectly assess the insulation status, with offline BDV tests used for confirmation.

Your Next Step

Dielectric strength is the bottom-line indicator of your insulating oil’s condition. Ignoring it means putting your valuable electrical assets at risk.

Contact us today to have our expert team provide precise BDV testing and condition assessment, ensuring your system remains safe and reliable!