Exceptional Measurement Accuracy

Utilizes high-resolution electronic measurement technology to precisely capture the turns ratio of transformer windings, ensuring data authenticity and repeatability, meeting stringent industry standards.

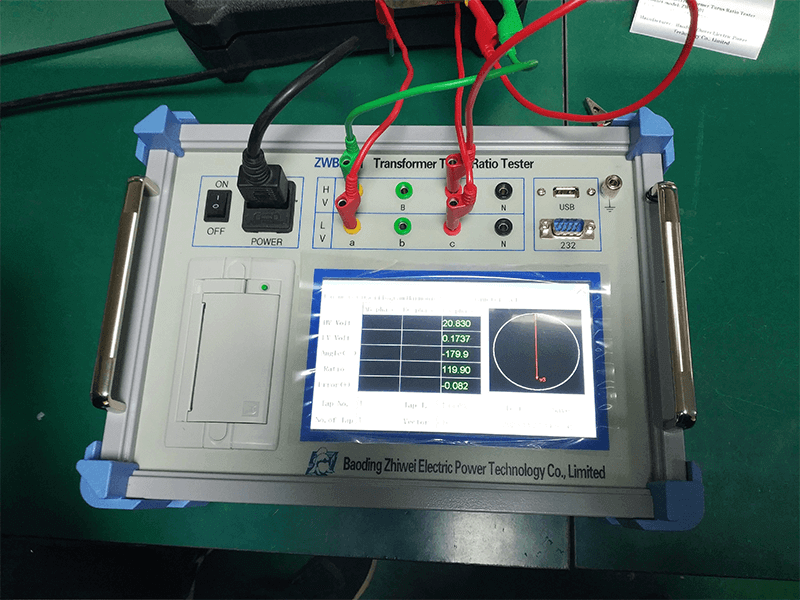

Our specialized transformer testing equipment is precisely designed to meet the rigorous demands of transformer manufacturing and full life-cycle maintenance.

Utilizes high-resolution electronic measurement technology to precisely capture the turns ratio of transformer windings, ensuring data authenticity and repeatability, meeting stringent industry standards.

Integrates automatic calibration and fault diagnosis functions to simplify operation, enhance testing efficiency, reduce human error, and improve maintenance quality.

Incorporates advanced filtering and shielding technologies to effectively resist electromagnetic interference and environmental noise, guaranteeing stable and reliable test results under complex field conditions.

Quality assurance, service first

The company specializes in the research and development, production, sales, and service of electric power system automation testing equipment, providing customers with one-stop services.

Our equipment has undergone strict calibration and testing to meet industry standards, ensuring high-precision power detection in various environments.

Our equipment design takes into account various environmental conditions, including extreme temperature and humidity, to ensure that it can function properly under all conditions.

The installation process is relatively simple. We provide detailed installation guidelines and can dispatch technical personnel to the site to assist with installation.

We provide comprehensive after-sales service, including equipment maintenance, troubleshooting, technical support to ensure that the equipment is always in the best condition.