Power quality refers to the condition of electrical energy in a power system; ideally the electricity takes the form of a perfectly symmetrical sine wave.

As industrial automation and electronic equipment become more widespread, power quality (PQ) has emerged as a key factor affecting production stability, equipment lifespan, and measurement accuracy.

This guide explains how the Power quality analyzers work, where to deploy them, and actionable best practices to help enterprises maintain stable power, reduce outage risks, and improve overall energy efficiency.

What Is a Power Quality Analyzer and Why It Matters

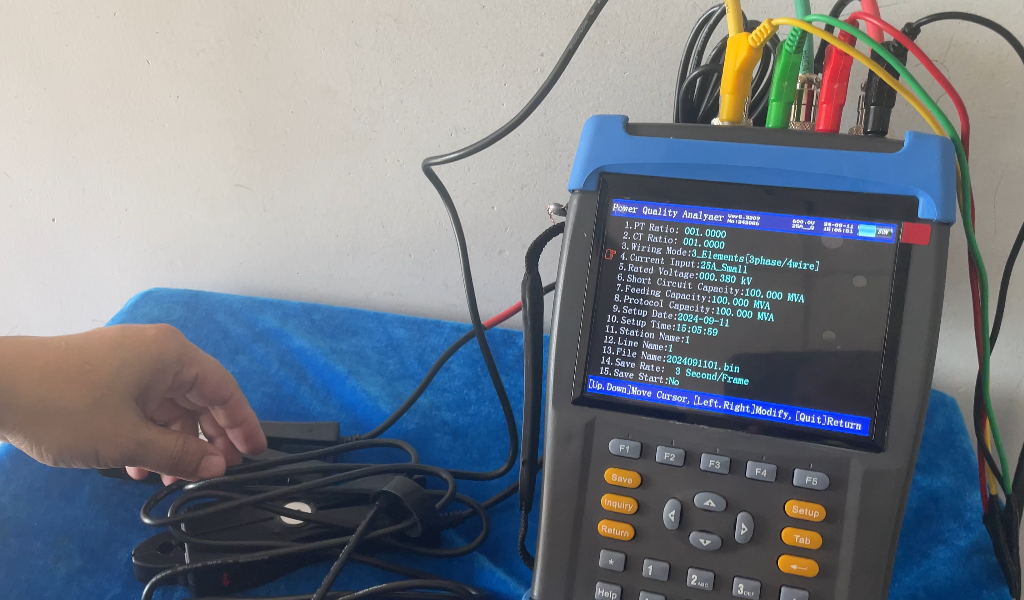

A Power Quality Analyzer is a sophisticated instrument designed to capture and analyze PQ events—such as voltage sags/swells, harmonics, transients, frequency shifts, and three-phase imbalances. It operates either in real-time or on a scheduled basis to provide a rigorous health check of your electrical system.

At its core, the analyzer precisely measures electrical parameters including voltage, current, and power factor. Beyond basic metering, advanced functionalities allow it to:

Analyze harmonics (typically up to the 63rd order);

Detect three-phase imbalance and flicker;

Display voltage/current waveforms and vector diagrams to verify wiring correctness.

Its importance is reflected in:

PQ analyzers provide both time- and frequency-domain evidence for incident forensics, making it easier to assign liability and pursue claims, particularly for brief, high-frequency events such as transients and voltage sags/swells.

Support long-term trend analysis to identify progressive issues in advance, such as accumulated harmonics that can lead to capacitor overheating.

It provides quantitative data for energy-efficiency optimization and reactive power compensation, reducing power losses and equipment failure rates—and thus directly impacting maintenance costs and production continuity.

Why Should You Have a Power Quality Analyzer?

Poor power quality can cause motor overheating, improper operation of variable frequency drives, PLC control errors, inaccurate readings from precision instruments, and lighting flicker.

Over time, it shortens the lifespan of capacitors, transformers, and insulation materials—raising the likelihood of failures and repair costs.

Moreover, many disturbances that lead to production interruptions (like certain harmonics or voltage sags) are not recorded by standard utility meters, making root-cause analysis longer and more difficult.

Having a PQ analyzer helps capture issues when they first appear, speeding diagnosis and reducing total cost.

Applicable Scenarios for Power Quality Analyzers

· Manufacturing workshops (large motors, induction furnaces)

· Data centers and server rooms (UPS and precision power)

· Hospitals (sensitive medical devices)

· Commercial buildings (elevators and lighting)

· Grid interconnection points (PV/wind inverters)

Portable analyzers are best for spot inspections and capturing specific transient events triggered by equipment startup. Fixed online PQ monitors are better suited for continuous trend analysis at critical distribution panels (PCC), allowing for centralized remote management.

Power Quality Analyzers Vs. Other Monitoring Tools

Different monitoring tools serve different purposes—here’s a practical comparison:

| Feature dimension | Power Quality Analyzer | Standard Energy Meter | UPS Built-in Monitor | Simple Data Logger |

|---|---|---|---|---|

| Application scenarios | Fault diagnosis, long-term monitoring, energy-efficiency optimization | Energy billing, basic load management | Power protection, battery management | Simple trend logging, long-duration data collection |

| Measurement accuracy | High | Medium | Medium | Medium |

| Transient capture | Strong | None or very weak | Weak | None or very weak |

| Harmonic analysis | Comprehensive (1st–63rd harmonics) | None | Weak | None |

| Waveform viewing | Yes (event waveform plots) | No | No | No |

| Event reporting | Detailed | None | Basic alarms | Simple timestamps |

Power Quality Analyzer Industry Use Cases

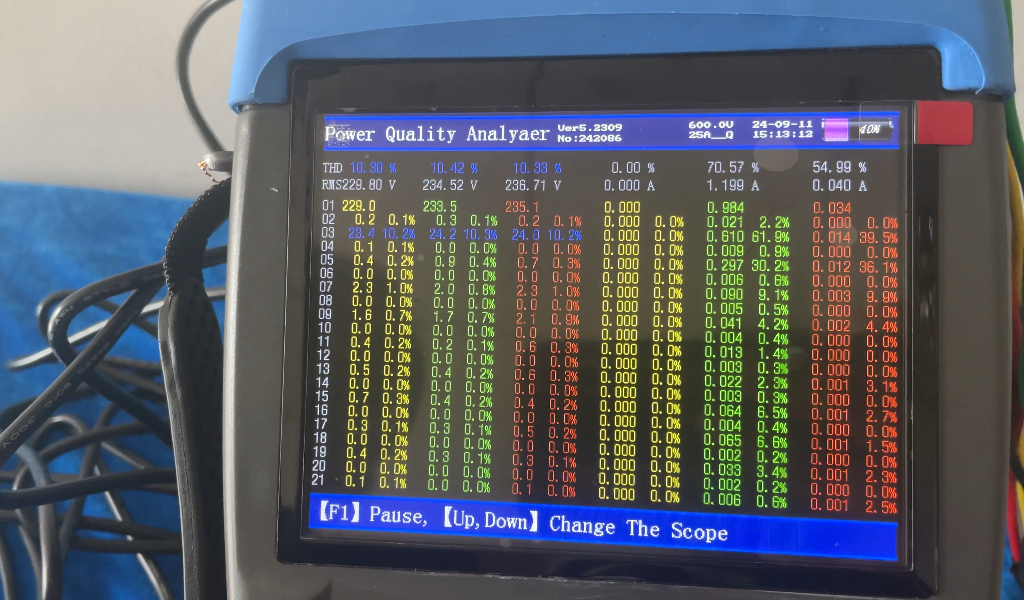

Analysis of data from a power quality analyzer at a 35 kV monitoring point in a plant showed total voltage harmonic distortion and the 3rd-harmonic voltage percentage exceeding international limits.

Simultaneously, 3rd, 5th, 7th, and other harmonic currents also exceeded international standards to varying degrees.

Given that the primary load on the feeder line monitored by this point is a fiberglass factory, a preliminary analysis suggests that the cause of these issues is likely related to this factory.

The main production equipment at this fiberglass factory is a glass melting furnace, which is a high-energy-consumption smelting device. During its operation, the glass melting furnace tends to cause three-phase load imbalance, distortion, and significant fluctuations, thereby generating a large amount of harmonics.

FAQ of Power Quality Analyzer

Q: Can a PQ analyzer replace a revenue (billing) meter?

A: No. Billing meters are used for legal metering, while PQ analyzers are used for quality monitoring and fault diagnosis.

Q: How is data saved and exported?

A: Most devices support local cyclic storage, removable SD cards, or cloud upload. Common export formats include PQDIF and CSV.

Q: How to deploy online PQ monitoring?

A: Install fixed monitoring units at critical distribution points. Collect data via Ethernet or wireless links and send it to a local server or cloud platform for remote real-time monitoring and alerts.

Q: Should PQ checks be done only after a fault?

A: Do both. Post-fault checks help identify the root cause. Regular inspections (e.g., quarterly or semiannually) reveal slow-developing issues, such as rising harmonic levels — often a precursor to failure.

Q: What causes harmonics and which orders are typically monitored?

A: Harmonics are caused by nonlinear loads such as VFDs, rectifiers, welding machines, and LED lighting.

PQ testing typically focuses on orders 2–50; in industry 3rd, 5th, and 7th harmonics are most common (3rd can overload neutrals, 5th can reduce motor torque).

Conclusion

Ensuring good power quality is fundamental to equipment safety, continuous production, and efficient energy use.

We recommend continuous online monitoring, along with periodic diagnostics, to detect and remediate emerging issues early.

Need a reliable solution for power quality monitoring?

We understand your critical requirement for data accuracy and system stability. ZHIWEI offers professional Power Quality Analyzers, specifically designed to precisely pinpoint harmonic interference, voltage sags, and three-phase imbalance.

Whether you need help with equipment selection, operation training, or follow-up advice on power system optimization, our technical team is always on standby.

Speak directly with our experts today to customize the most cost-effective maintenance strategy for your facility.