Trace moisture significantly reduces the dielectric strength of oil, accelerates oxidative aging, and generates acidic by-products that corrode internal metal components. Precise measurement of moisture content in transformer oil is a critical practice in the operation and maintenance (O&M) management of power equipment.

This article systematically analyzes the core logic of transformer oil moisture measurement, provides solutions for high-moisture scenarios, and helps you formulate scientific maintenance strategies.

The Impact of Moisture on Insulation Performance

1. Impact on Dielectric Strength (Breakdown Voltage)

The core functions of transformer oil are insulation and heat dissipation. Moisture drastically reduces its dielectric strength. Since water molecules are polar, they align under the influence of an electric field, forming conductive channels that can eventually lead to insulation breakdown or short-circuit faults. Even trace amounts of moisture can induce partial discharge.

2. Accelerating Cellulose (Insulation Paper) Aging

The cellulose materials inside a transformer, such as insulation paper and boards, are the “primary carriers” of moisture. A dynamic equilibrium exists between the moisture in the oil and the moisture in the paper. Water participates in the hydrolysis of cellulose, breaking down its molecular structure. This causes the insulation paper to become brittle and lose mechanical strength. Simultaneously, this process produces acids that further corrode internal metallic components, significantly shortening the transformer’s service life.

3. Risk of Bubble Formation at High Temperatures

During load operation, the transformer oil temperature rises. When the temperature exceeds 80°C, moisture dissolved in the oil may precipitate rapidly due to changes in saturation, forming microscopic bubbles. The dielectric strength of these bubbles is far lower than that of transformer oil; they are easily broken down in high-voltage electric fields, triggering partial discharge. In severe cases, this can lead to carbonization of the insulating oil, creating permanent fault risks.

Sources and Forms of Moisture in Transformer Oil

The sources of moisture in transformer oil are diverse: firstly, residual moisture from the manufacturing process; secondly, the ingress of external moisture during operation; and thirdly, trace moisture produced by oil oxidation and decomposition, which is a by-product of oil aging.

Regarding its physical state, moisture in transformer oil primarily exists in three forms:

Dissolved Water: Evenly dispersed in the oil to form a stable solution. This is the primary form of moisture existence.

Free/Emulsified Water: When moisture content exceeds the oil’s saturation solubility, it suspends in the oil as microscopic droplets. This state has poor stability.

Bound Water: Moisture chemically combined with oxidation products or additives in the oil. This is difficult to remove through conventional methods.

Understanding Moisture Metrics: PPM vs. Relative Saturation (%)

Before selecting a measurement method, it is essential to understand two easily confused concepts: PPM and RS%.

1. Metric Comparison Analysis

| Comparison Dimension | PPM (Parts Per Million) | Relative Saturation (RS%) |

|---|---|---|

| Core Definition | The mass of water contained per million parts of oil (Unit: mg/kg or ppm). Reflects absolute content. | The ratio of actual moisture in the oil at a specific temperature to the maximum moisture solubility of the oil at that temperature. Reflects saturation degree. |

| Temperature Correlation | None. The value does not change with temperature (as the total mass of substance remains constant). | Strong correlation. For the same oil sample, the higher the temperature, the lower the RS% (as the oil’s capacity to hold water increases). |

| Essential Attribute | Quantitative Metric (Fixed Value) | Qualitative/State Metric (Relative Status) |

| Industry Role | Basis for standard compliance (IEC/IEEE limits). Can be directly used for compliance judgment. | Risk warning indicator. Used to judge the probability of water precipitation (Emulsification/Free water). |

| Application Scenario | Laboratory precision testing, equipment acceptance, periodic compliance verification. | Online real-time monitoring, moisture trend analysis, fault early warning. |

| Data Characteristics | Intuitively comparable. Numeric values possess reference consistency across different scenarios. | Must be interpreted in the context of temperature. A standalone value has no absolute significance. |

| Conversion Relationship | Acts as the conversion basis. Requires solubility curves (isotherms) + temperature parameters to convert to RS%. | Requires temperature and the oil’s A/B parameters to reverse-calculate to PPM. |

2. The Impact of Temperature on Moisture Solubility

Temperature has a significant impact on moisture solubility.

At low temperatures, oil solubility is low, and a small amount of moisture can cause the RS% to reach saturation, forming emulsified or free water. At high temperatures, the oil’s solubility increases, allowing more moisture to exist in a dissolved state. But the PPM value of the same oil sample remains unaffected by temperature changes.

Common Measurement Methods and Principles

Currently, transformer oil moisture measurement methods are divided into laboratory precision measurements and on-site rapid measurements. Each method has specific application scenarios and technical characteristics:

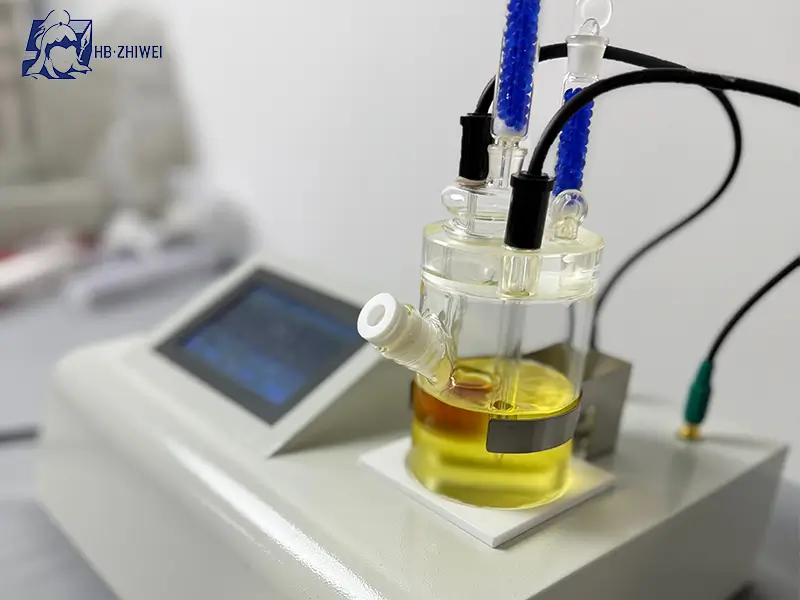

1. Karl Fischer Titration (GB/T 7600 / ASTM D1533)

Karl Fischer Titration is the internationally recognized benchmark method for moisture measurement. It is primarily divided into Volumetric and Coulometric methods, both widely used for precise laboratory measurements.

The principle is based on a specific chemical reaction between the Karl Fischer reagent and water: I₂ + SO₂ + 3C₅H₅N + H₂O → 2C₅H₅NHI + C₅H₅NSO₃. The moisture content is calculated by measuring the amount of reagent consumed.

Volumetric Method: Suitable for samples with moisture content >10 ppm.

Coulometric Method: Higher sensitivity, capable of measuring trace moisture <10 ppm with an accuracy of up to ±0.1 ppm. It is the preferred method for arbitration/referee testing. But this method requires professional personnel and a controlled laboratory environment.

2. Moisture Sensor Method (Online On-site Measurement)

With the development of intelligent power O&M, online monitoring based on capacitive sensors has been widely adopted.

The principle involves detecting changes in the oil’s capacitance to calculate Relative Saturation (RS%) and then converting this to PPM based on temperature.

Its response speed is relatively fast (less than 1 min) and operation is extremely convenient, making it especially suitable for real-time field monitoring. However, it is significantly affected by oil temperature and impurities, and its measurement accuracy is relatively lower, typically around ±2~5 ppm.

Table: Core Differences (Based on Industry Practice)

| Comparison Dimension | Laboratory Karl Fisher Titration | Online Capacitive Sensor |

|---|---|---|

| Measurement Metric | Absolute Moisture Content (ppm) | Relative Saturation (RS%) + Converted ppm |

| Accuracy Level | High (Error ±0.1ppm) | Medium (Error ±2ppm) |

| Testing Efficiency | Offline, takes 1-2 hours | Online, real-time response |

| Applicable Scenario | Precision verification, equipment acceptance, standard compliance | Daily monitoring, trend analysis, risk warning |

| Operational Cost | Requires professional staff, reagent consumption | One-time installation, long-term maintenance-free |

| Environmental Impact | Samples easily contaminated by air humidity | No secondary contamination, continuous data |

Recommended Strategy: Use online sensors for daily monitoring and utilize laboratory methods for precise verification when anomalies are detected.

Interpreting Moisture Content: Industry Standards (IEC & IEEE)

1. Acceptable Limits for New and In-Service Oil

New Transformer Oil (Pre-energization): IEC 60296 requires moisture content ≤10ppm, IEEE C57.106 recommends ≤15ppm, to ensure the equipment starts with good insulation status.

In-Service Transformer Oil: Limits are stricter. Typically requires ≤20ppm. If the equipment has been in operation for over 10 years or operates under high load, it is recommended to control moisture at ≤15ppm to reduce aging risks.

2. Limits Based on Voltage Class

Different voltage classes of transformers have significantly different sensitivities to moisture, with high-voltage equipment requiring higher insulation standards:

| Voltage Class | IEEE C57.106 Recommended Limit | IEC 60814 Recommended Limit |

|---|---|---|

| <69kV | ≤30ppm | ≤25ppm |

| 69-230kV | ≤20ppm | ≤15ppm |

| >230kV | ≤10ppm | ≤10ppm |

Note: For ultra-high voltage transformers (≥500kV) in critical substations, the industry typically adopts stricter internal control standards (≤8ppm) to ensure long-term stable operation.

FAQs About Transformer Oil Moisture

Q1: What is the normal PPM level for transformer oil?

For in-service transformers, generally control it below 10-20ppm (depending on voltage class): Low-voltage equipment (<69kV) can be relaxed to ≤30ppm, while high-voltage equipment (>230kV) must be strictly controlled at ≤10ppm.

Q2: How often should transformer oil be tested for moisture?

For main transformers, it is recommended to conduct a moisture test at least annually. If the equipment is aging, heavily loaded, or has shown signs of moisture previously (such as excessive partial discharge), the testing frequency should be increased to every 3-6 months. If online monitoring equipment is installed, data can be reviewed in real-time without extra periodic sampling.

Q3: Why do laboratory test results (PPM) differ from online sensor readings?

This discrepancy is common, primarily due to two reasons: ①Temperature Effect: Lab samples are tested at room temperature, while online sensors measure oil at operating temperatures. Converting to standard PPM involves solubility curves, and temperature differences cause deviations.

②Different Metrics: Online sensors measure RS% and convert to PPM. If the oil parameters (A/B parameters) used for conversion are inaccurate, the result will deviate.

Q4: If the oil test shows very low moisture (dry oil), can we guarantee the insulation paper is dry?

No. Over 99% of the moisture in a transformer is absorbed in the insulation paper, not the oil. In low-temperature environments, moisture is “locked” in the paper, creating a “dry oil, wet paper” phenomenon. At this point, the oil sample passes the test, but the insulation paper remains damp. Only when the transformer is at a stable high temperature (≥60°C) and moisture migration between paper and oil reaches equilibrium can the oil sample truly reflect the water content of the insulation paper.

Q5: How do I choose between “Volumetric” and “Coulometric” Karl Fischer methods?

For transformer oil samples with trace moisture (ppm level), you must choose the Coulometric method. The volumetric method has lower precision and is typically used for chemical products with higher water content; it is not suitable for insulating oil testing.

Q6: Can “filtering” the oil permanently solve high moisture problems?

Usually not. Ordinary filtration can only remove free water and some emulsified water from the oil; it cannot dry the insulation paper. Severely damp transformers require online drying systems (running for several months) or vapor phase drying processes to thoroughly dry the solid insulation materials.

Conclusion

Moisture measurement and scientific control in transformers are key factors in ensuring the safe operation of power equipment. When formulating maintenance standards and testing frequencies, one must consider the equipment’s voltage class and operating years, avoid the “dry oil, wet paper” misconception, and select the appropriate measurement combination (Online Monitoring + Precision Verification).

Looking for High-Precision Testing Solutions Compliant with IEC/ASTM Standards?

We understand the rigorous requirements laboratories have for data accuracy. ZHIWEI provides industry-leading Karl Fischer moisture titrators, specifically designed for trace moisture detection in insulating oil, fully compliant with ASTM D1533 and GB/T 7600 standards.

Whether it is equipment selection, operational training, or subsequent oil treatment advice, our technical team is ready to assist you. Contact our technical team directly to tailor the most cost-effective maintenance strategy for your needs.